Session 7:

Feeding and chopping devices on a forage harvester

Aims of the session:

At the end of the session, you will be able to…

- name and describe various chopping devices on forage harvesters.

- explain how to adjust chop length.

- evaluate the role of machine maintenance in prolonging the working life of a forage harvester.

Note:

Before operation of any machine make sure you familiarise yourself with the following:

- Risk assessment

- Adherence to industry safety guidance and operator’s manual

- Safe start and stop

- Monitoring of machine performance and output

- Effective communications

- Clearance of blockages

- Conversion between work and transport positions

- Economic operation

- Safe and efficient operation.

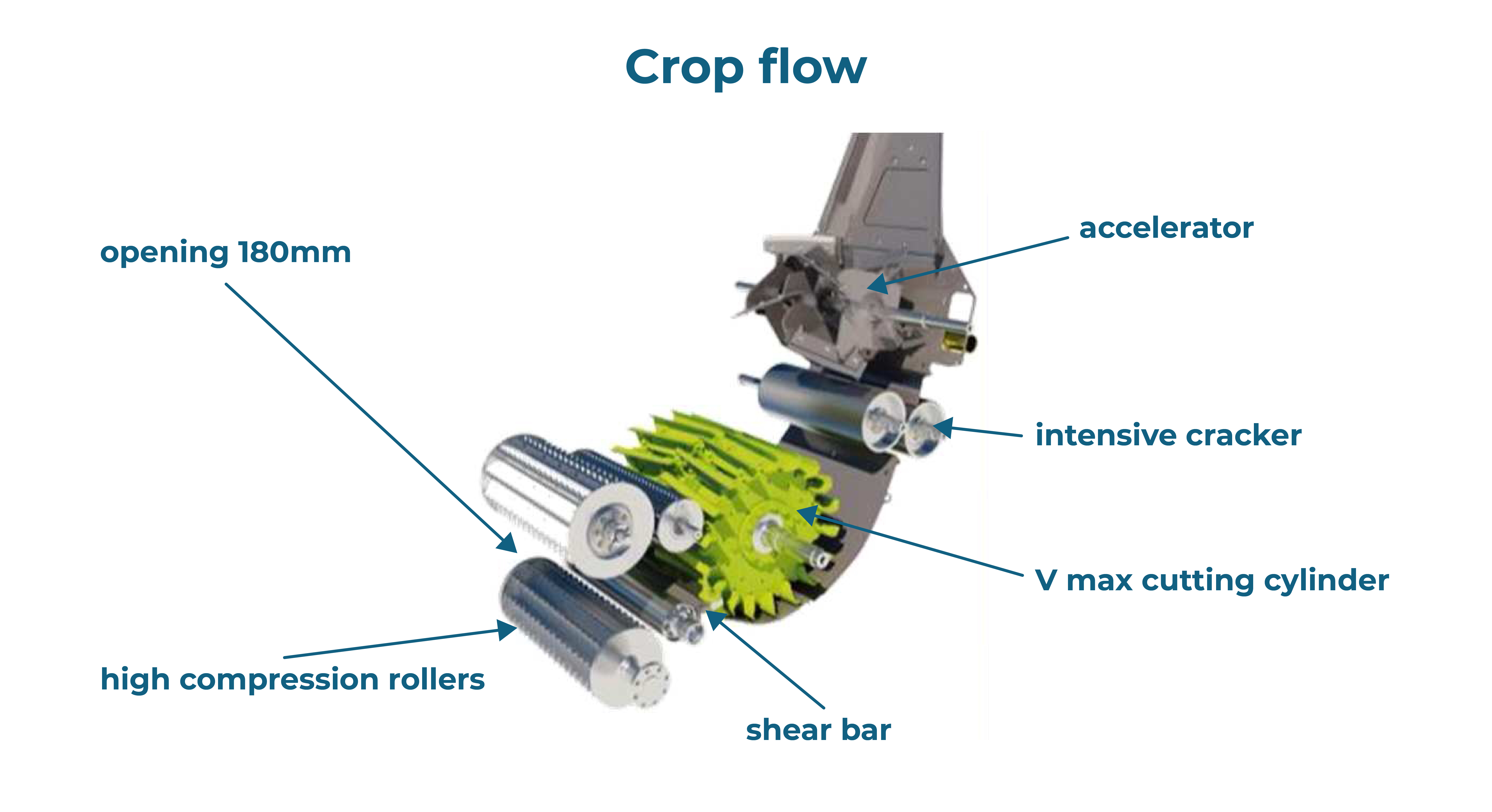

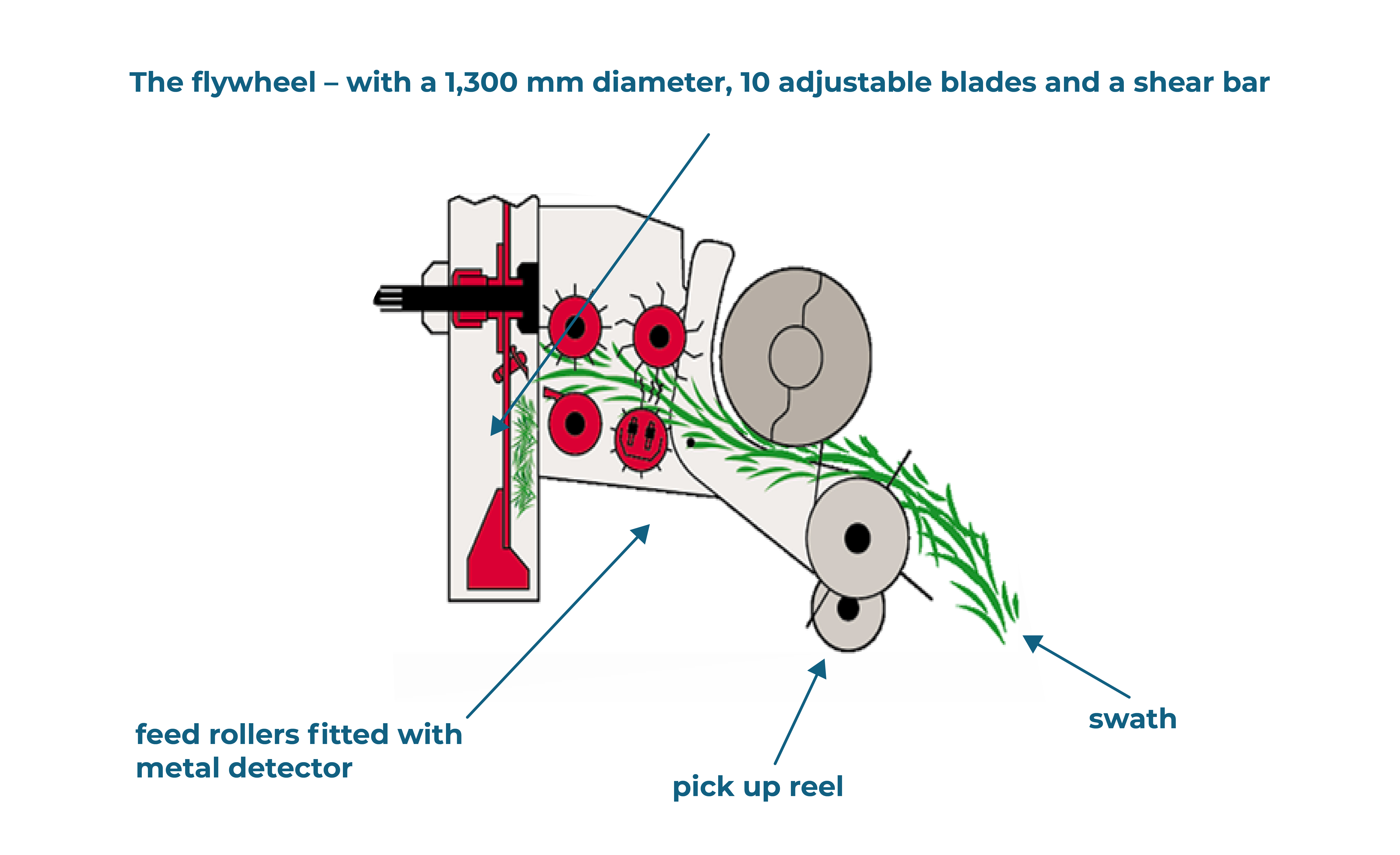

Feeding and chopping system

Class exercise

- How many feed rollers are there?

- What is the maximum opening?

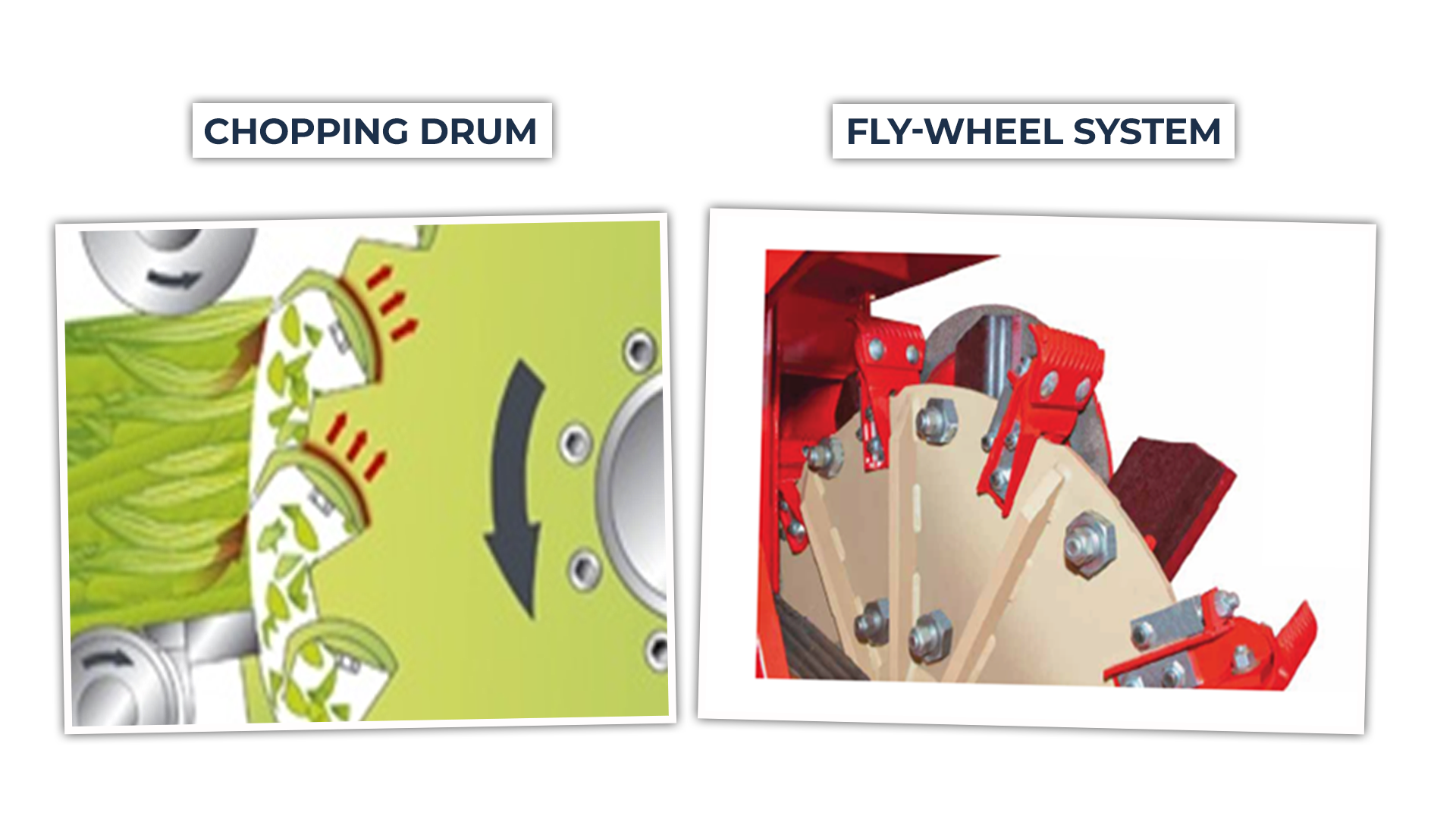

- Type of cutting cylinder?

- How can you improve crop flow?

- Draw a diagram showing crop flow and highlighting these factors.

Easy adjustment of chopping length

By changing the gears in the gearbox, the operator can quickly adjust the chopping length within the range from 6 to 44 mm without having to use any tools.

Summary

At the end of this session, you will now be able to…

- name and describe various chopping devices on forage harvesters.

- explain how to adjust the chop length.

- evaluate the role of forage harvester maintenance in prolonging its working life.