Session 9:

Forage harvester crop processors (corn cracker)

Aim of the session:

- To explain why some crops need to be fed through the corn cracker.

- To show various types.

- How to adjust various components.

- To show how maintenance is carried out.

Note:

Before operation of any machine make sure you familiarise yourself with the following:

- Risk assessment

- Adherence to industry safety guidance and operator’s manual

- Safe start and stop

- Monitoring of machine performance and output

- Effective communications

- Clearance of blockages

- Conversion between work and transport positions

- Economic operation

- Safe and efficient operation.

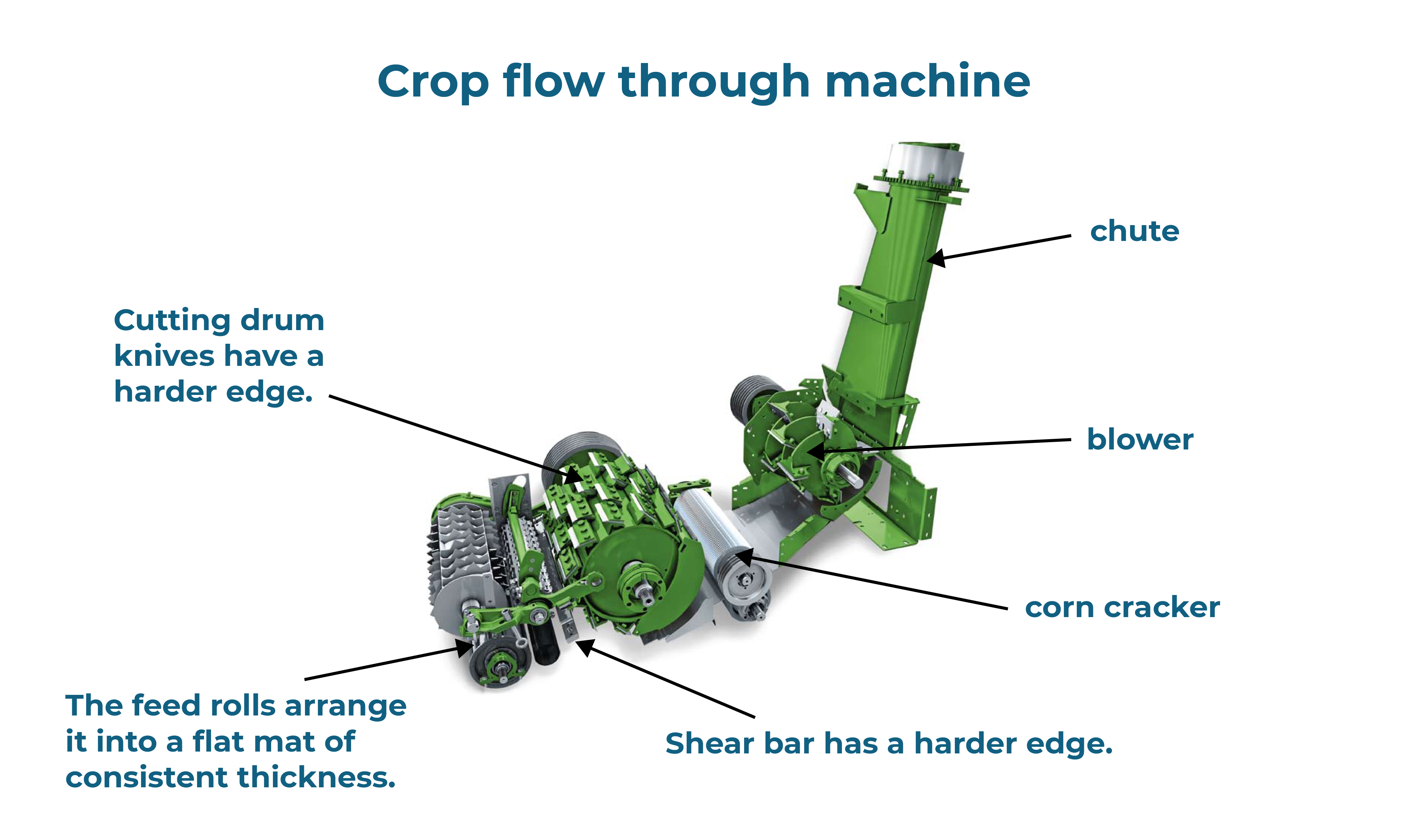

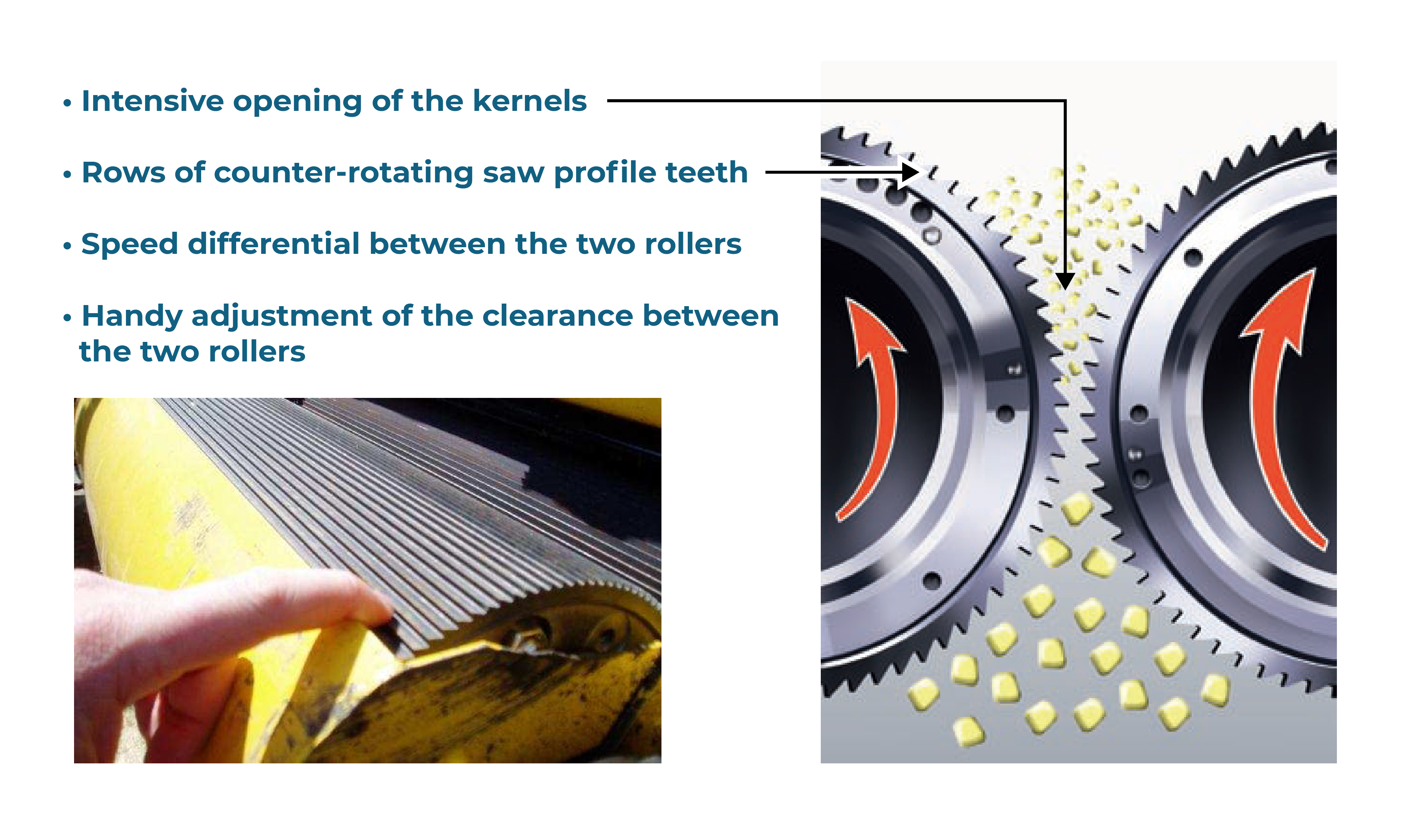

Maize silage is one of the most important forage products. To ensure that maximum nutritional value can be extracted, every kernel needs to be cracked open.

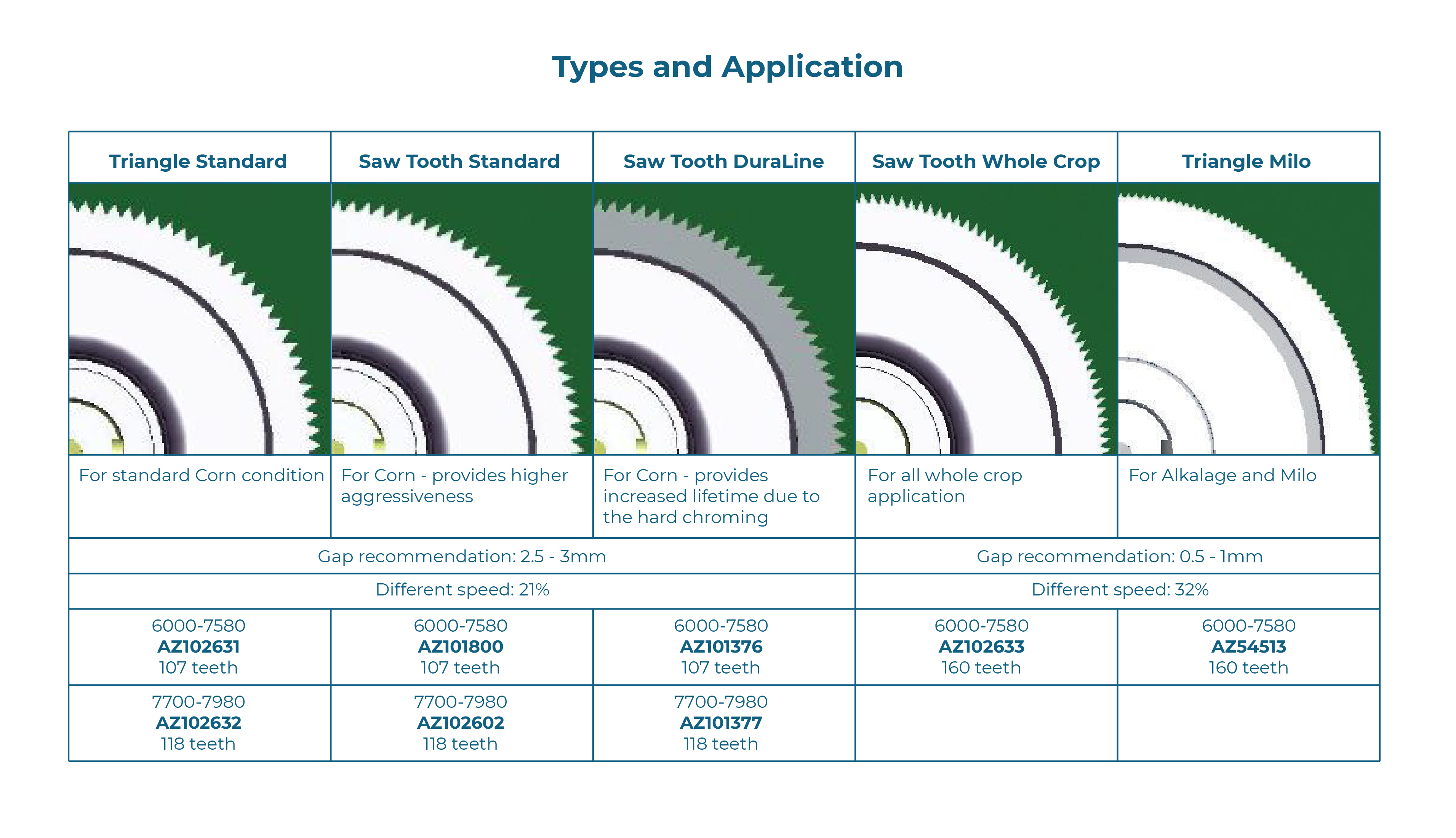

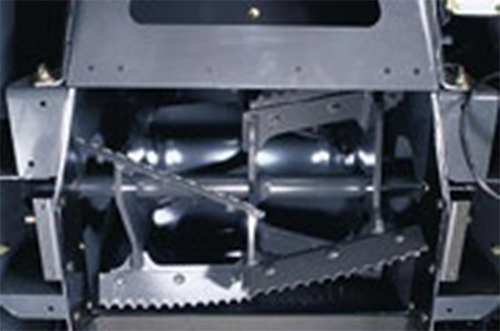

Different types of corn crackers

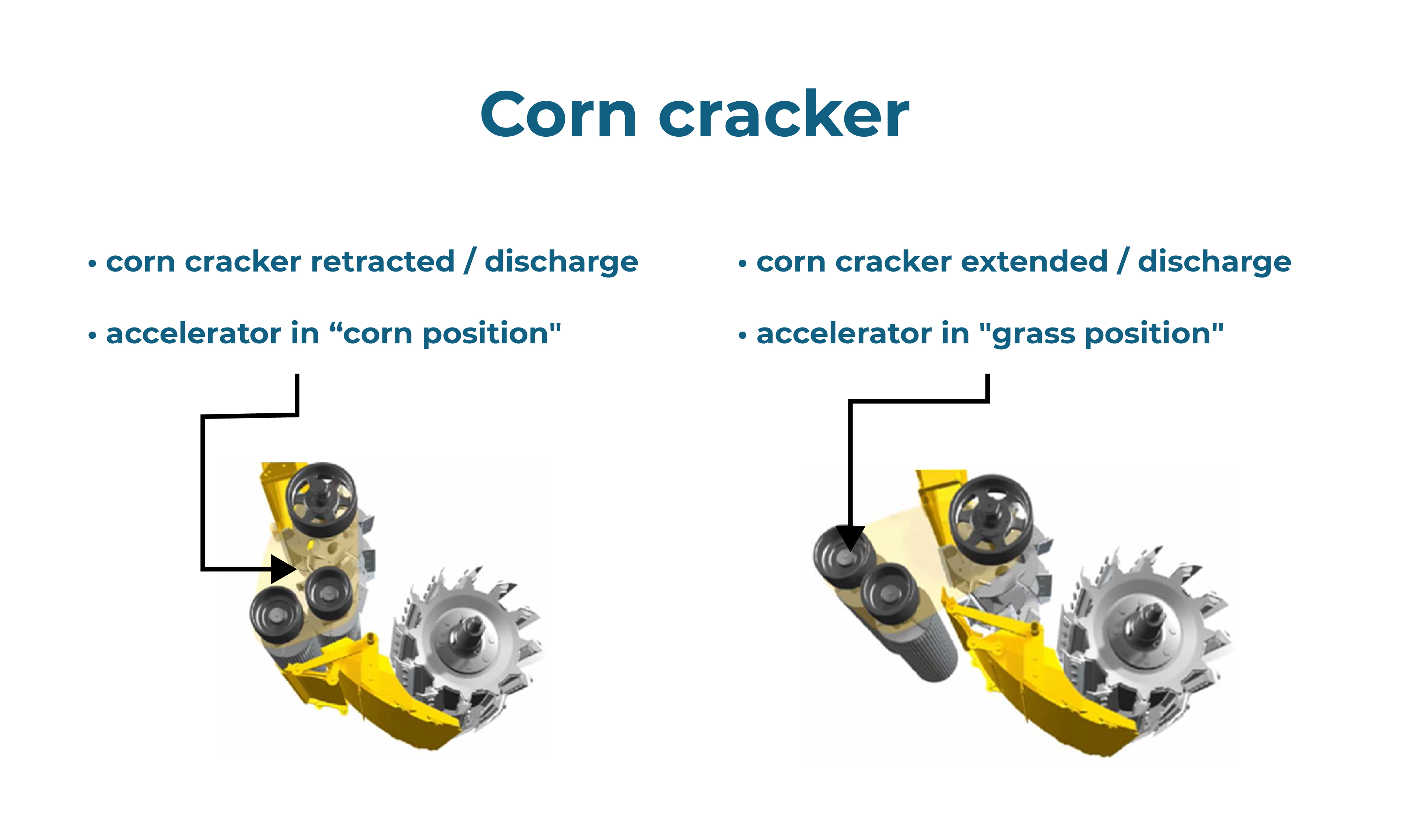

Accelerator

When the chopped material does not require a high blowing force, simply increase the gap – this reduces the power requirement as well as wear and tear.

For higher discharge rates, reduce the gap.

You can control and adjust everything easily either mechanically or via CEBIS in the cab.

Removable accelerator plates

Discharge chute

- 210° rotating angle is possible; some machines have a greater movement.

- Automatic parallel guiding of the filling point on the trailer is available.

Class exercise – List maintenance requirements on feeding and cutting mechanism.

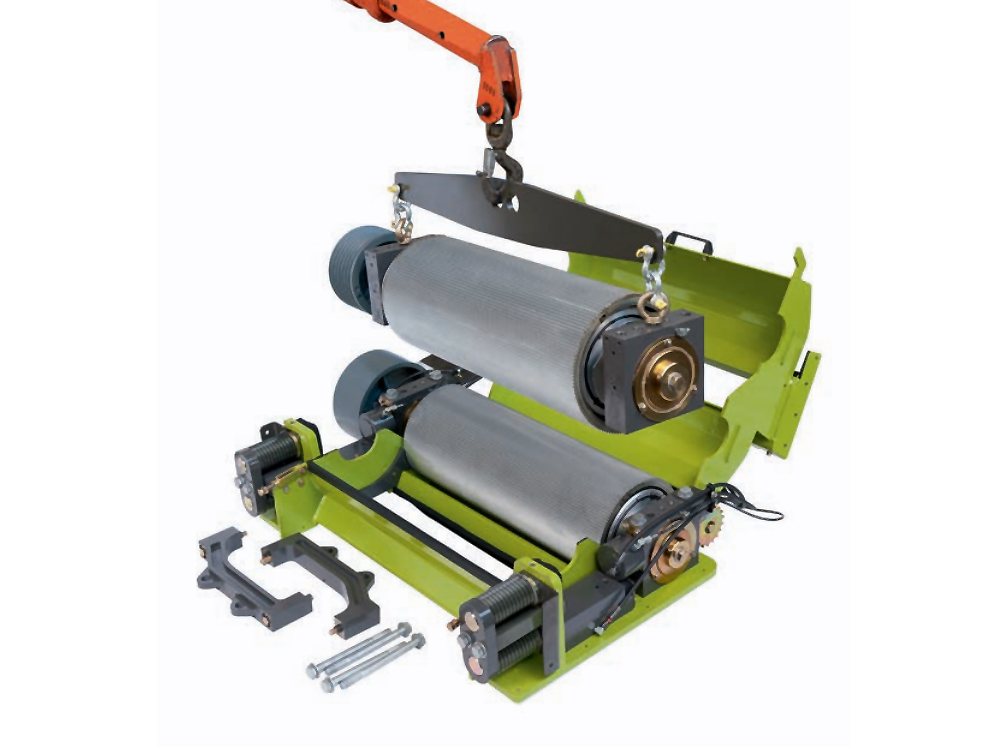

Clean and inspect the feed rolls and inspect the right hand feed roll drive gearbox.

Inspect the gearbox shafts for excessive “play”, also grease.

Grease all universal joints.

Blow out and clean debris and dust from the knife grinder housing.

It’s also important to clean this area frequently during the season.

It must be cleaned before sharpening the cutter head knives to prevent fire.

Clean residue from sharpening stone also check condition and wear and damage, adjust if fitting or adjusting blades.

Check all knives, also check for wear and damage. Rotate drum and check for balance.

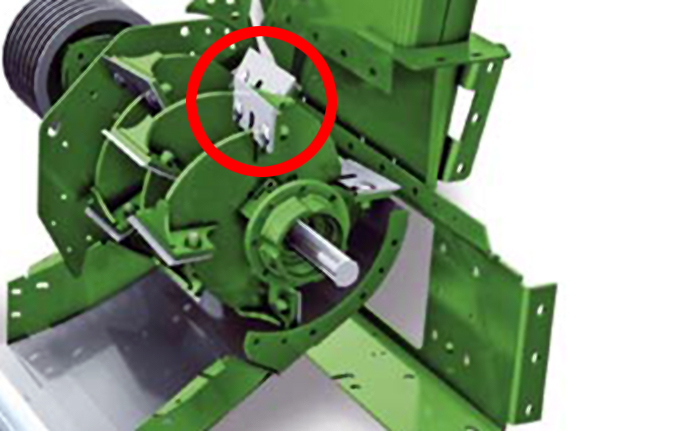

Check knife clearance is 0.5mm across full face of the knife.

Re-cap on lesson

- What is the purpose of the corn cracker?

- How can the accelerator be adjusted?

- How often should the knives be sharpened?

- How is the clearance set for the knives?