Session 8:

Introduction To Large Square Balers

Aim of the session:

- To show how the big square baler works.

- To show various crops that are being harvested.

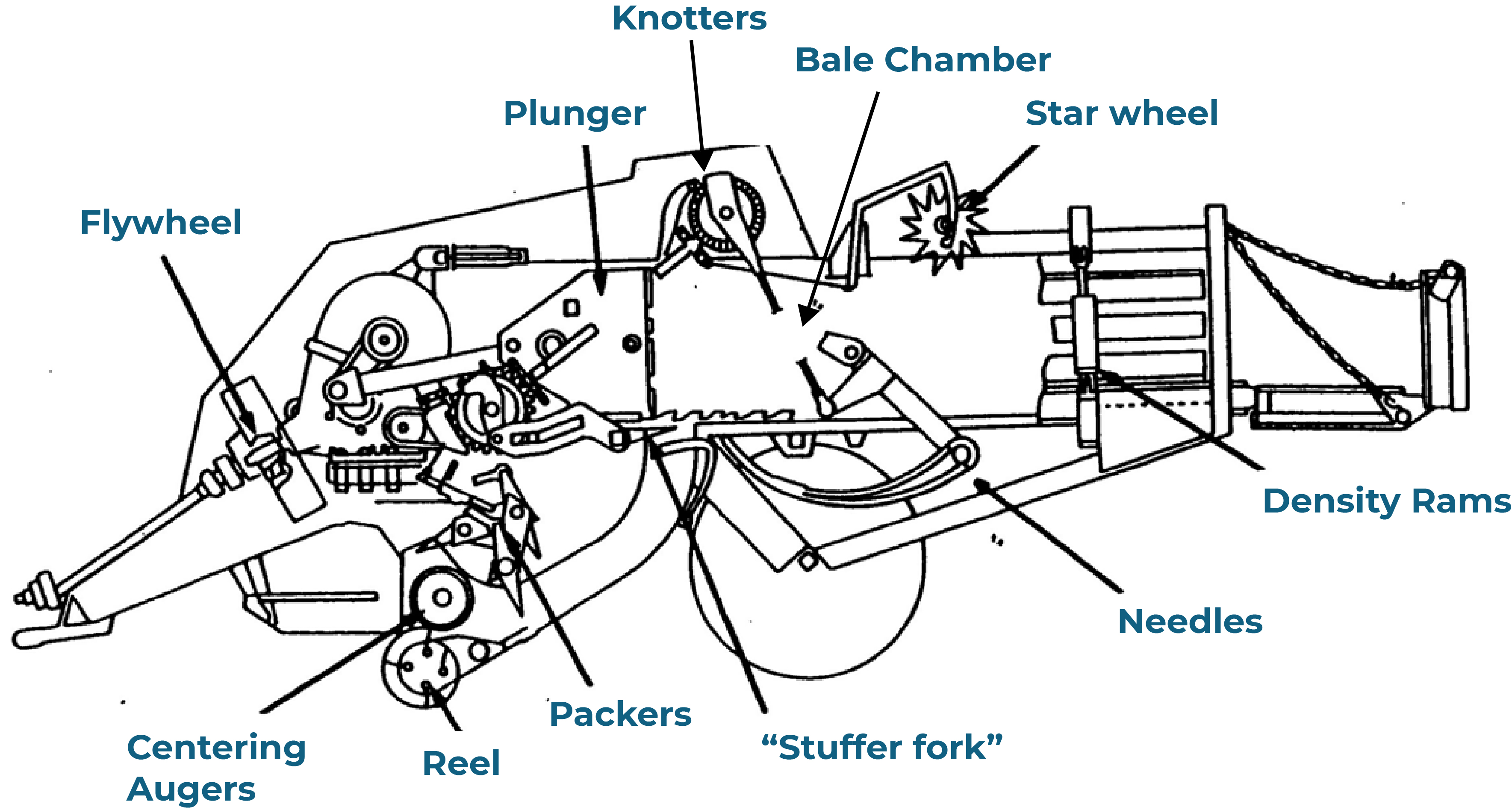

- Show the various parts of the baler.

Objectives

- To explain the working principle of the baler.

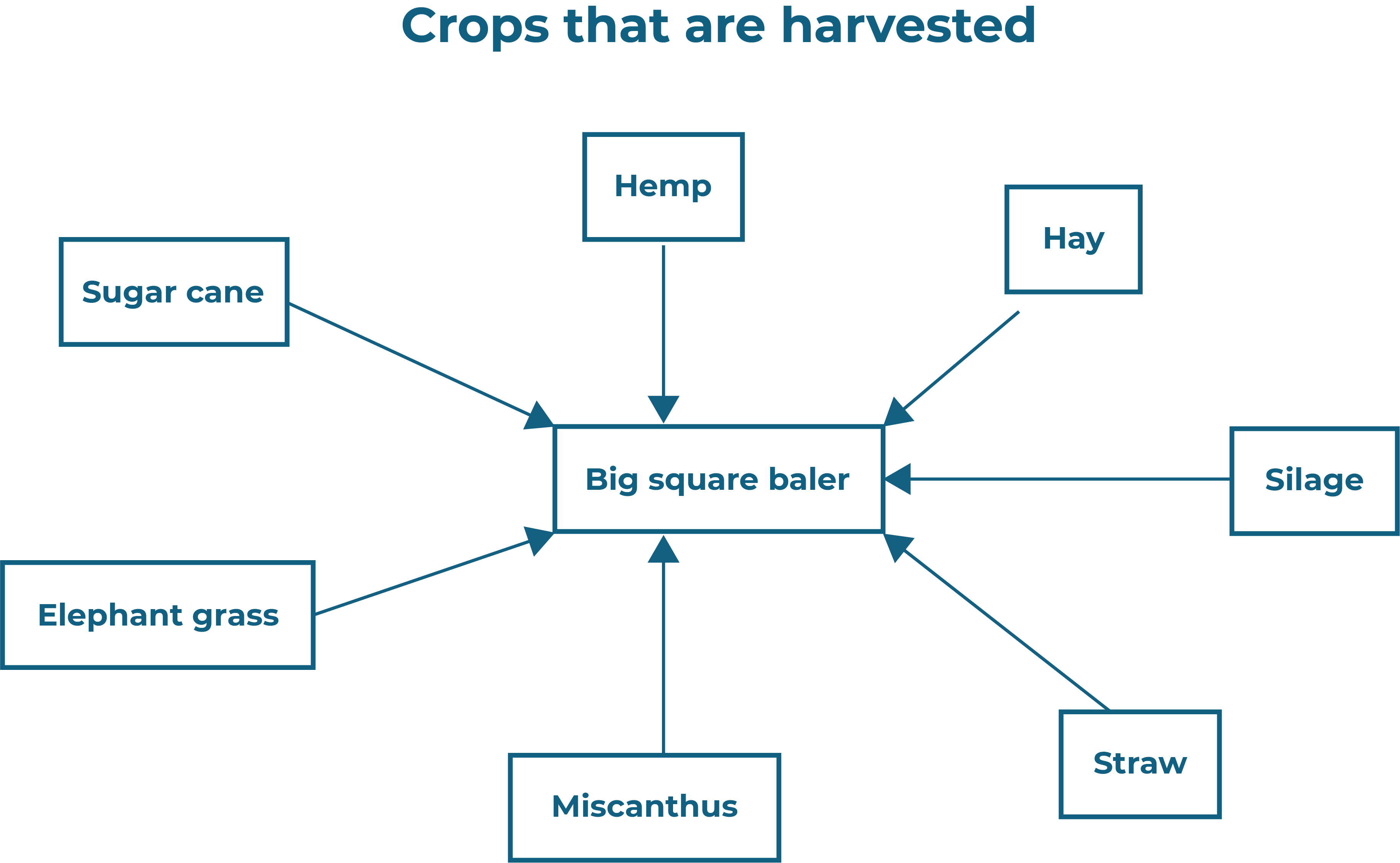

- Explain various crops that are harvested.

- Recognize the various working parts of the baler.

Note:

Before operation of any machine make sure you familiarise yourself with the following:

- Risk assessment

- Adherence to industry safety guidance and operator’s manual

- Safe start and stop

- Monitoring of machine performance and output

- Effective communications

- Clearance of blockages

- Conversion between work and transport positions

- Economic operation

- Safe and efficient operation.

Big Square Balers:

Who makes them?

How does the Baler Work?

Parts of the baler

How does the Baler Work?

Function of the big square baler

Function of the big square baler

A baler picks up the crop from a swath, and compresses it into a large rectangular bale.

The largest big square bales can weight up to 1 ton.

- Unlike the small baler, the width and height of the bale can vary.

- Modern big square balers vary in chamber size.

- Also a chopper mechanism is available to chop the length of the crop.

Principle of Operation

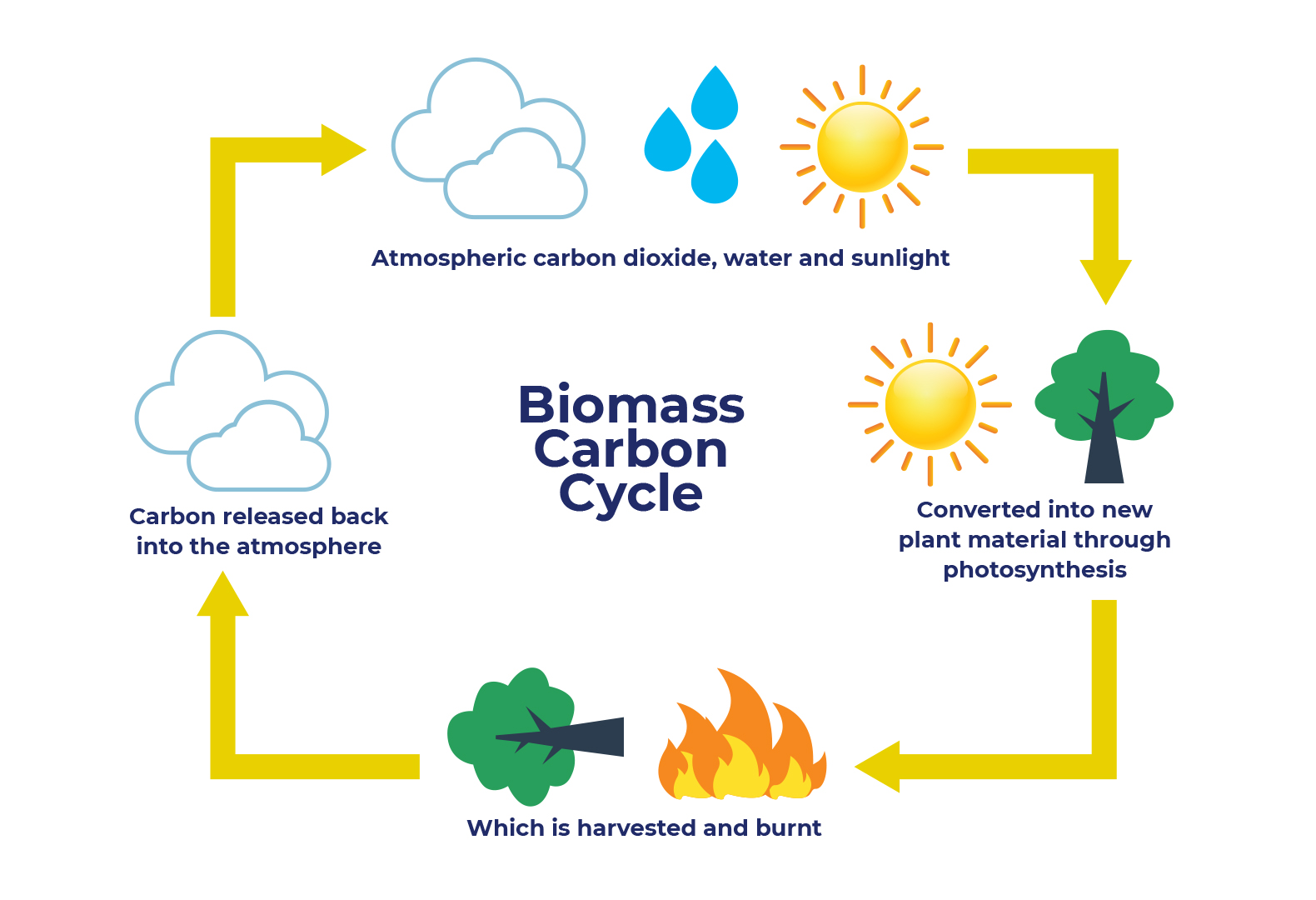

What is biomass?

Biomass is any plant-derived organic material available on a renewable basis. Carbon released into the atmosphere when the material is burned is equivalent to the amount absorbed by the plant during its growth cycle.

This type of fuel can take many forms - from crops like barley that is specifically grown for use in power stations to by-products such as straw.

Bale Transportation

Power Stations

Power stations require big square bales

Plants are built around the bale size for:

- high density

- uniform shape

- reduced transportation due to size

- bales hold their shape after hauling from field to plant

- ease of storage

How Big Square Balers are used to harvest sugar cane by-products in Malawi

Swath ready to be baled by the baler

NH BB-A - Case IH LBX baler

Recap on lesson

- How does the big square baler work?

- The crops that can be harvested using the square baler.

- Recognize the various parts of the baler.